Cannock Chase Mining Historical Society

Presents

A DAY IN THE LIFE OF

The accounts that follow are actual accounts by ex-coal miners of what their working day was like down the mine. It has to be said though that very rarely were any two days the same.

A Day in the Life of a 19th Century Pit Boy

By Dennis Jackson in the boyís local dialect (translated).

ďMe nairme (name) is Sammy Tomson an I was born in 1820 so that meks me 10 years ode. I cor (can not) remember me mam or dad so me wum (home) is the union wairkeouse in Chapel Street. We call it the dump.

I got up at harf past five this mornin, ad a swill (wash) and a round of bread and jam, collected me snap (meal), walked wiv me mairtes (mates) to the pit a mile away and got down the shaft at harf past six just as the buzzer was guin. We nearly got buzzed (too late). It ay arf code down theer. The Butty (Contractor) was wairtin for us at the pit bottom an sent me to me usual job on Wilkins stall in the 5 foot thick Deep Seam an its better theer cus its warmer an sum of me mairtes ay far off but the Doggy (Buttyís Assistant) meks sure we get to the fairce (coal face) straight off.

Me fust job is to get underneath Wilkinís stall (part of coal face) weer its bin oled out (undercut) an rairke (rake) out the gummins (small coals) so that Wilkins can sling um into the gob (waste area behind). He let me av a go once but is shovel is a big square un an I like the Banjos (pear shaped). Once ode Wilko starts getting his big coal down I av to put it in me basket an drag it to the way end (junction) weer the oss (horse) will tek it to the shaft an its ard cus sumtimes he drops grairte big lumps an I cor lift em in me basket but the hoss driver will elp me at the way end to get em out. If Wilko wants some timber supports e tells me to bring a leg on the way back to the fairce.

I cor count so George the hoss driver said to put a mark on a tree (roof support) evry time I bring a basket out and he will count for me.

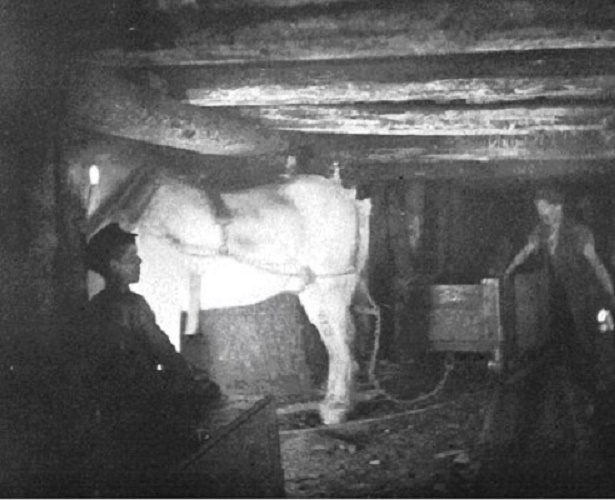

Ere is me wiv George and his hoss Paddy; heís a big un eh he?

This young lad is "trapping"he was employed to open the air door on the sound of a pony approaching and close the door after the paony and tubs had gone through all this he did in the darkness.

Iím pretendin Iím the gaffer and geein (giving) George his orders. George as got a bucket lamp but I doe get none Ė theym too evey. I get the candle.

At about harf pas eleven its snap time an George sez Iíve dun 68 baskets so far. All we lads av to sit together so the Butty can give us is orders and sometimes a bit of a cussin (telling off). I've got bread an cheese agin today but he always giz us a tut (cup) of ale an it ay harf nice instead of wairter (water). He tode me today that Iím a proper apprentice now til Iím 21 an then I can get into the big money. Sumtimes I sit wiv the big men and luv to listen to em talking and see em taking snuff. I ay tried it yet but I might try a chew of baccy sumtime.

Iím among me mairtes there's 10 lads here but not all am apprentices yet. The Butty's givin us orders

The Butty or Pufler he got the men work and paid them out on a Friday

He also tode me over snap that tomorrow alf day he wants me to go trappin(g); thatís mindin an air (ventilation) door an openin an shuttin it as the osses cum by. I doe like it cus I av to sit in the dark an listen for the osses cumin. They used to av women and gels on that job but they only wairke on the bonk (pit surface) now.

Back to the grind an another three or fower (four) ours of coal draggin an George sez Iíve done 102 all togever. The last part of the shift is elping the men drag timber to the fairce an most of em nick (help themselves) to a bit of cockwood (firewood) then its time for Lilleycock (end of shift) an back up the shaft to a bit of sunshine . We might get a gairme of football in befower dark.

Its Friday today an itís the best day of the wik cus the men can av a draw on the reckonin (what is owed) and we get paid. The men get coin money most of the time but sumtimes they get paid in ale an their women doe like it an sumtimes in tommy (tokens) to spend at the Tommy shop. They tell me that the Butty owns the Tommy shop. I get 5d (pennies) (2p pence) pocket money a wik an the Butty darenít pay me in Tommy cus they wo allow me in the shop.

Me other mairtes am ere now an itís nearly quarter to five so we av to get back to the dump or weíll miss our dinner. Most of us am filfy (dirty) so itíll tek a bit of time to get a good wesh (wash) in the sink. I ope you enjoyed me wairke day. Itíll probably be the sairme next Monday. Am yo cumin wiv me?Ē

Authorís Note.

Sammy worked at one of the deeper mines in the south of the coalfield where the system of mining was Longwall Stalls.

Parliament passed the Coal Mines Act 1842 on the 10th August 1842 which began: -

ďWhereas it is unfit that women and girls should be employed in any mine or

colliery, and it is expedient to make regulations regarding the employment of

boys in mines and collieries, as to make provision for the safety of persons

working therein.

This Act prohibited all female labour in coalmines; the employment of boys under

the age of 10 years in coal mines and provided for a system of inspection.

It did not affect people employed above ground.

The law was amended in 1860. The Mines Inspection Act of 1860 required boys between the ages of ten and twelve to have a school certificate before they could be employed.and restricted their hours of work to 54 a wik Ė sorry, week.

Before the above act schools in some pit villages

were unheard of, deemed by the Ďbetter peopleí to be unnecessary when working

life for pitmenís children could start at six or seven with a working day as

long as seventeen hours. What time was there for school? What learning was

necessary for pit work?

The Truck system was made illegal under an Act of Parliament dated 1831 thus making payment by 'Tommy' illegal.

However, this legislation was not totally effective. In most areas of the UK, coal and ironmasters continued to use truck tokens intermittently until the passing of the Truck Amendment Act of 1887.

___________________________________________

A Day in the Life of a 20th Century Mining Trainee

By Dennis Jackson

"My name is Gordon Ferris and I was born in 1936 at the end of the war. I am now nearly 19 and have completed my Entrants and Basic Underground Training under my Mining Apprenticeship with the National Coal Board. I also go to the Mining College one day and evening a week on the third year of the National Certificate in Mining. I hope to go on to become an official and maybe a Manager some day. It wonít cost me anything. In the meantime, I am doing my coal face training (18 is the earliest age for this), I have already done 40 days getting and loading at the face and now I am on to the 20 days of cogging. Getting and cogging work shifts about here Ė 1 week days, the next afternoons Ė so this week I am on noons. Mom doesnít cut me any snap (food) because we get good cheap food in the canteen; all I take is an apple and sometimes an onion which makes the other men in the team downwind swear at me.

I change into my pit clothes, always lovely and warm if not clean, in the pit head baths, collect my cap lamp and check (counting tally), have a fag as I walk up to the pit top (making sure I donít have any cigs or matches on me) and get down the shaft with some of the team just before 3pm else we get buzzed (late). Itís a deep shaft but it only takes a few minutes to get to the pit bottom and then we have a walk of about ĺ of a mile to get to the face of 301ís Benches Seam which is about 5 ft thick.

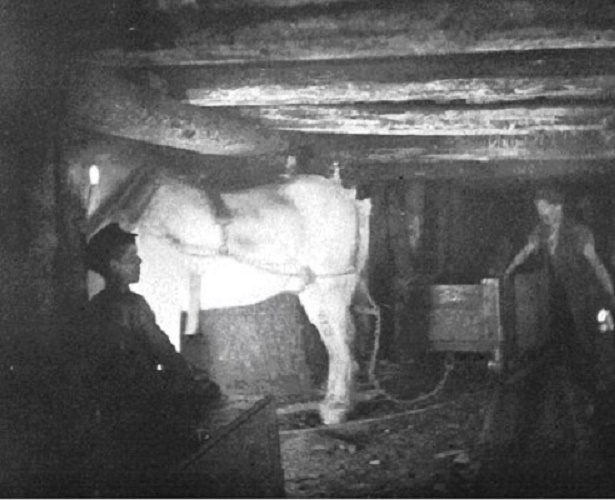

The first job is to assist the conveyor turnover team to break up the conveyor pans ready for them to re-assemble in the new track (shown dotted). Until the old track is clear, we canít remove the roof supports, known as legs and bars, which support the roof behind the new conveyor line as the cog is built up. For this, we use a Sylvester (ratchet lever) and chain. The Sylvester is fixed to a timber wedge against the roof, the chain wrapped around the top of the support and, with a few pulls on the ratchet lever, the leg is usually free. Another leg has to be pulled to release the bar supporting the roof.

This is repeated for other legs and bars in our stint (length

of cog). For our safety, we erect quick action steel legs to give us temporary

support while building the cog. Then we can get on with building our individual

cogs which are stone packs built from broken down roof rocks.

Each

cog or pack is about 5 yards long and has to be extended by 4ft 6ins which is

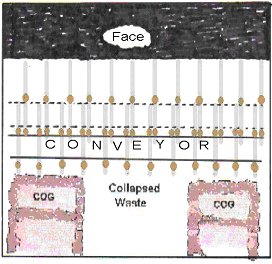

the depth of the turnover. Thatís me behind my Supervisor in the second picture

and Iím building a cog side with big rocks (and we canít always get them Ė

theyíre sometimes too big and sometimes too small). To get the cogging material

the waste has to be brought down behind the timber supports and more often than

not we have to drill a big hole upwards into the roof and the shotfirer inserts

a Hydrox shell which he fires. It sure does bring down the roof but the stink is

awful from the burnt gasses in the shell. We are supposed to withdraw all timber

from the cog area using the Sylvester again but we have occasionally left one if

itís impossible to get out because of the roof weight. We try to get it hidden

before the Deputy comes along.

Each

cog or pack is about 5 yards long and has to be extended by 4ft 6ins which is

the depth of the turnover. Thatís me behind my Supervisor in the second picture

and Iím building a cog side with big rocks (and we canít always get them Ė

theyíre sometimes too big and sometimes too small). To get the cogging material

the waste has to be brought down behind the timber supports and more often than

not we have to drill a big hole upwards into the roof and the shotfirer inserts

a Hydrox shell which he fires. It sure does bring down the roof but the stink is

awful from the burnt gasses in the shell. We are supposed to withdraw all timber

from the cog area using the Sylvester again but we have occasionally left one if

itís impossible to get out because of the roof weight. We try to get it hidden

before the Deputy comes along.

Right, so we start to extend the cog and the Supervisor is shovelling smaller rock between the side walls while I build. For him itís easier to use a Banjo (pear shaped) shovel because the square shovel tends to dig in a bit further. Coal dust and small coal must not be used because it might cause spontaneous combustion (self heating) in later months.

Seven o-clock is snap time. We only take about 15 minutes but itís enough to keep you going along with a pint of water or cold tea. Iíve brought an onion, an apple AND some baked beans today and they all wonder what that smell is! Occasionally we get a brave mouse come and try to pinch a bit of bread but they get the apple core. We all eat in the tail gate where itís a bit warmer.

Back to the cog. By now the walls are pretty near the pans so the front wall has to be built a bit more slowly so that the smalls can be slung in to tightly pack up to the roof. Large rocks can go in but they either go in before the walls are built Ė and then you run out of big stuff Ė or youíve got to lift them over the wall. If the afternoon Under Manager comes on the face heís always poking his officialís stick (like a walking stick) into the finished cog to make sure there are no voids. I did say to him yesterday that come Lilleycock (end of shift) the roof weight will do that. He wasnít amused! The idea of the cog is to STOP roof lowering and so give support to the coal face area.

Iíve only got 5 more days of cogging training to complete and then I think the Training Officer will put me on conveyor turnover (moving forward) which is nightshift. Days, noons or nights I always work the 5 shifts a week to get the bonus shift.

Weíve got about 35 minutes before Lilleycock and it will take about 20 minutes to get outbye so weíve got time to cut a bit of cockwood (firewood). Because my Dad doesnít work in the mines I get the monthly coal allowance of 18 cwts and we do like our coal fires; theyíre great for toasting bread.

Its now 11.10 pm and were heading for the baths where we all except one put our pit clothes in the dirty lockers, get a lovely hot shower and soaping then to the clean lockers to get into normal dress. The one exception is an older noon shift worker who is either shy, wants to get home to his wife (??) or is too old fashioned. He goes home on the bus. Thereís nothing left at this time of night for pleasure but the canteen is still open and I fancy a bacon sarnie (sandwich) and whatever else they have. Three cheers for the NCB. Good night."

Authorís Note.

Gordon successfully completed his statutory 2 years at the coal face, gained his First Class Certificate of Competency, emigrated to Australia and became a Mine Manager down under.